Quality Performance

Requires Quality Pads

The Largest Manufacturer of Sanding Pads

A Strong History In Foam

From Humble Beginnings to World Wide Reputation

Our Below Strengths Have Made Us a Favorite of Fortune 500 Tool and Abrasive OEMs

Customer Reviews

Work With Us

We Offer Two Avenues to Successful Pad Sourcing

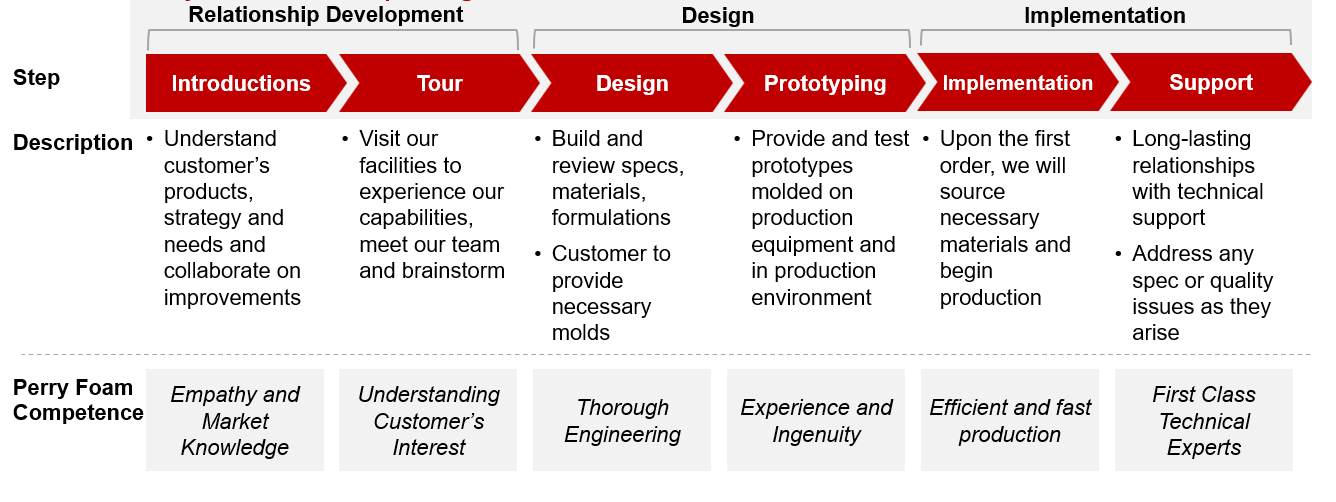

We Provide a Dedicated Relationship Management Process from Introduction to After-Sale Support

Knowledge Base

For all general purposes: Yes.

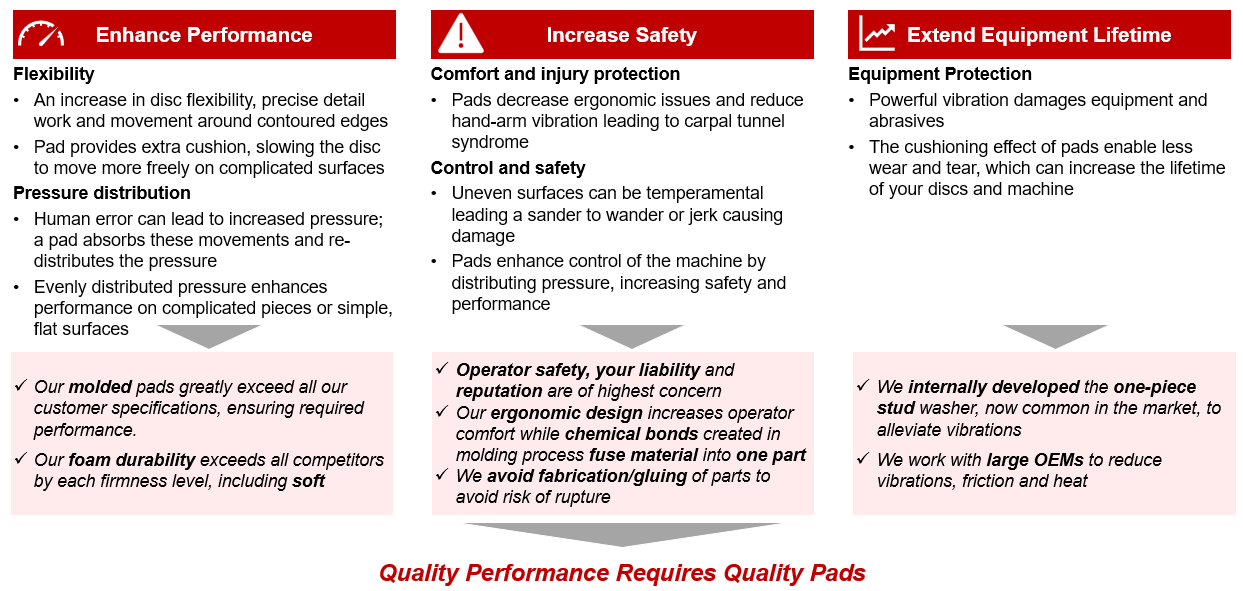

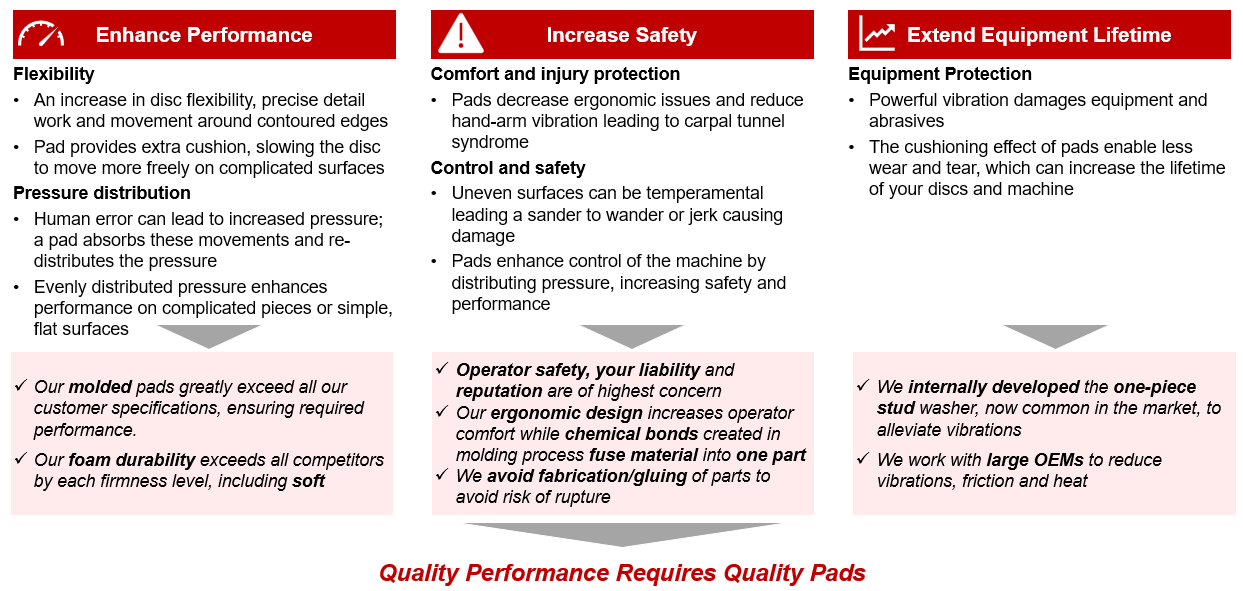

In short, sanding pads enhance performance of your tool, increase operator safety, and extend equipment useful life.

Your tool or abrasive is judged in the marketplace based upon the results of the application.

You can't control the operator or the application, but you can prepare your tool or abrasive to be used appropriately by providing a quality back-up pad.

Don't leave this integral part of the abrasion dynamic to the operator.

If a bad pad is used, this will reflect negatively on your tool or abrasive, as the performance and results will suffer. Protect your brand with high performing pads.

Quality Performance Requires Quality Pads

If a bad pad is used, this will reflect negatively on your tool or abrasive, as the performance and results will suffer. Protect your brand with high performing pads.

Quality Performance Requires Quality Pads

Cheaper pads may be a good short-term solution depending on the tool and application, but they likley won't last or perform at desired levels.

This will become apparent in performance and abrasion quality. If the pad is weak, it may tear, break, or dent, causing inconsistencies in the evenness of the sanding/abrading.

Cheaper pads are typically of less quality and will need to be replaced more often. This could end up being more expensive than acquiring a quality pad from the onset.

This will become apparent in performance and abrasion quality. If the pad is weak, it may tear, break, or dent, causing inconsistencies in the evenness of the sanding/abrading.

Cheaper pads are typically of less quality and will need to be replaced more often. This could end up being more expensive than acquiring a quality pad from the onset.

It depends on a few factors: your tool, your application, and your budget. Our experts are happy to assist.

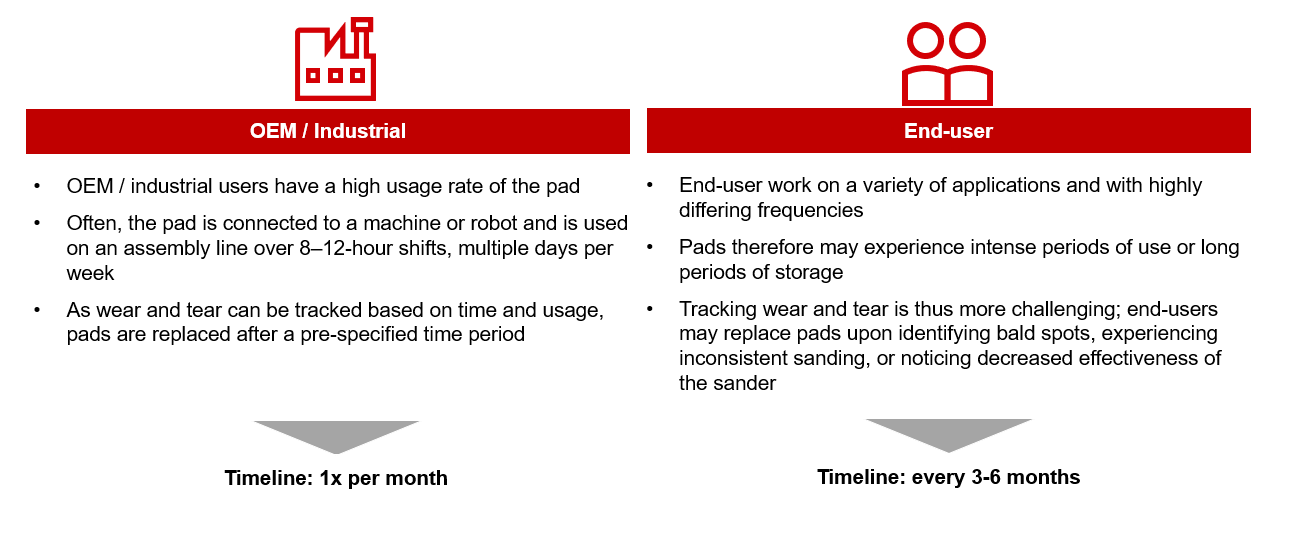

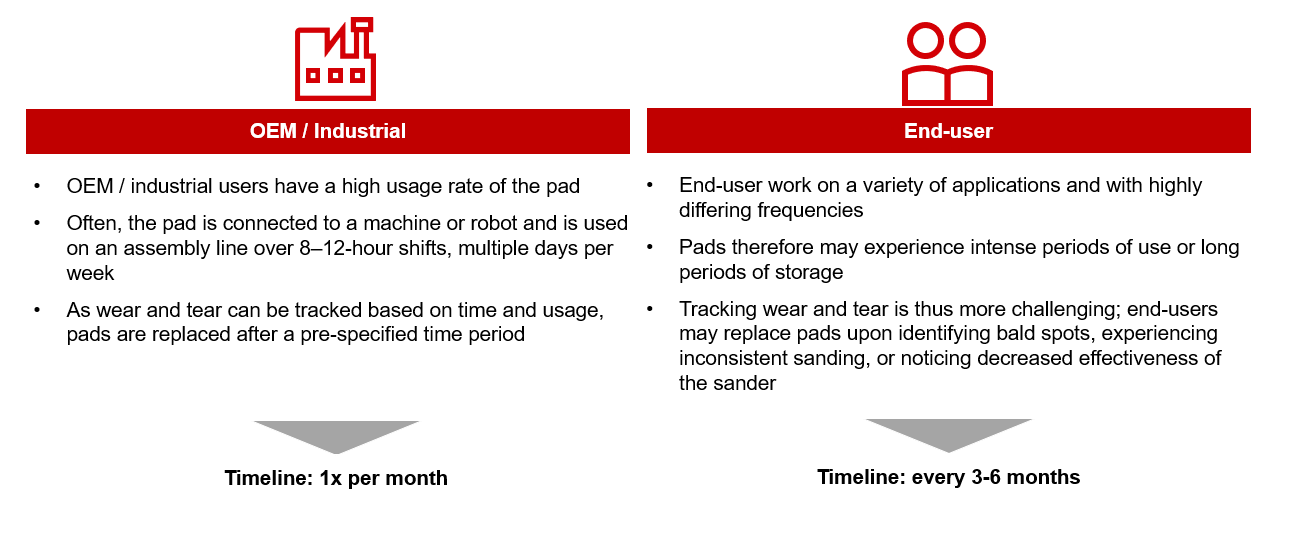

Pad replacement depends on the frequency of use and characteristics of the application. Here's a guide.

The various hole patterns are associated with dust collection. In general, the more holes, the more capabilities for collecting dust in use.

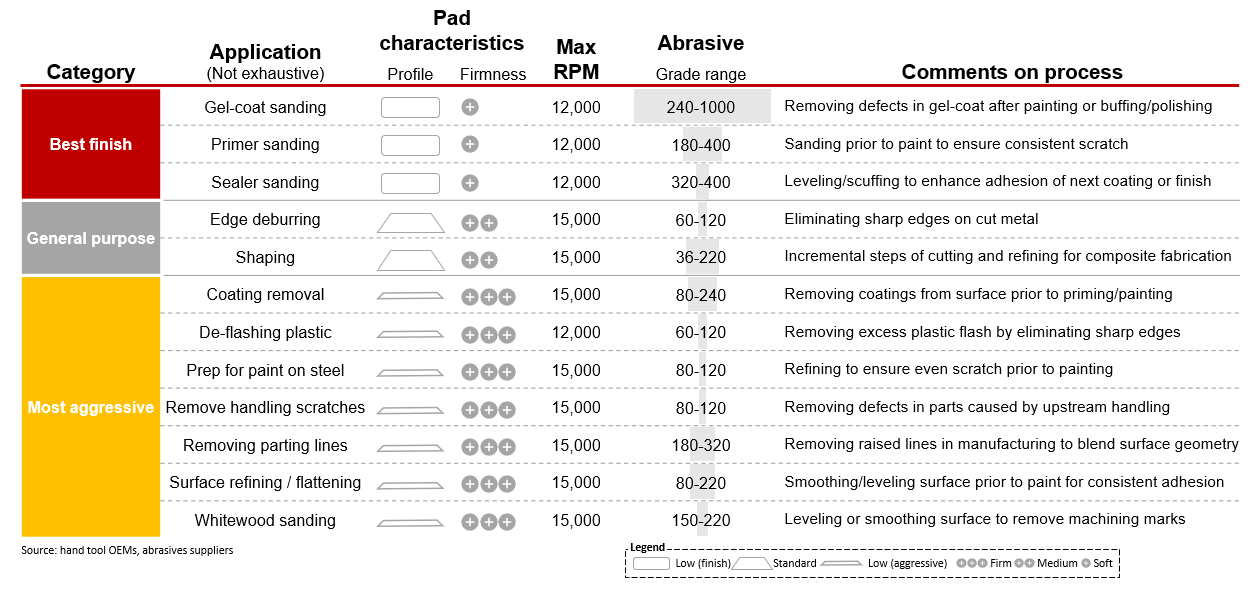

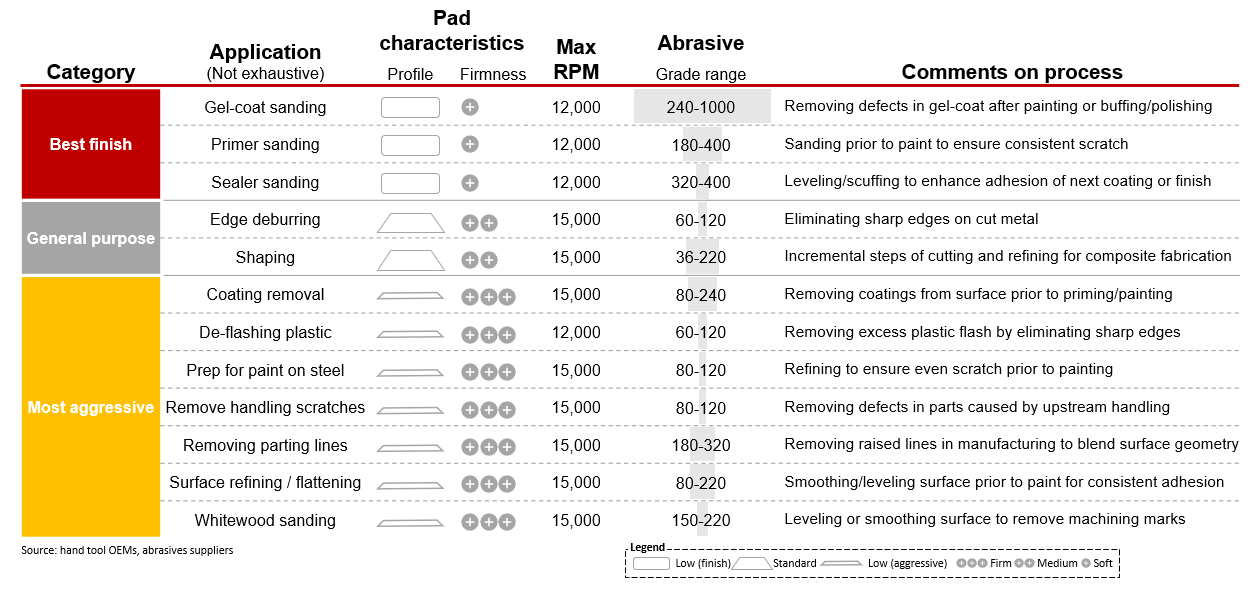

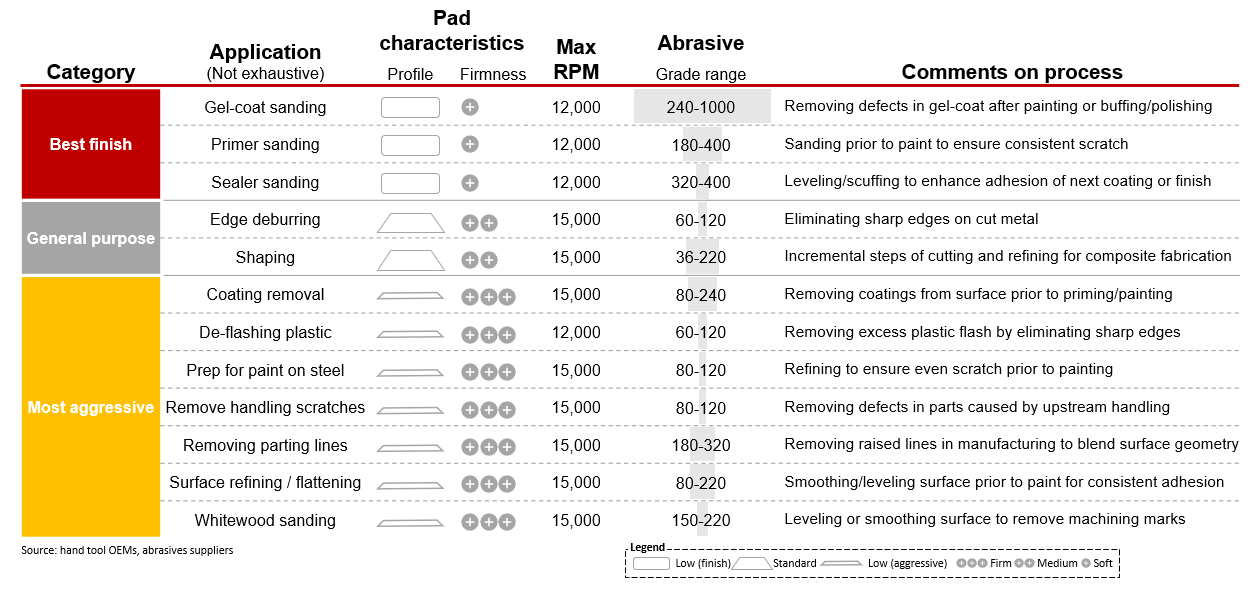

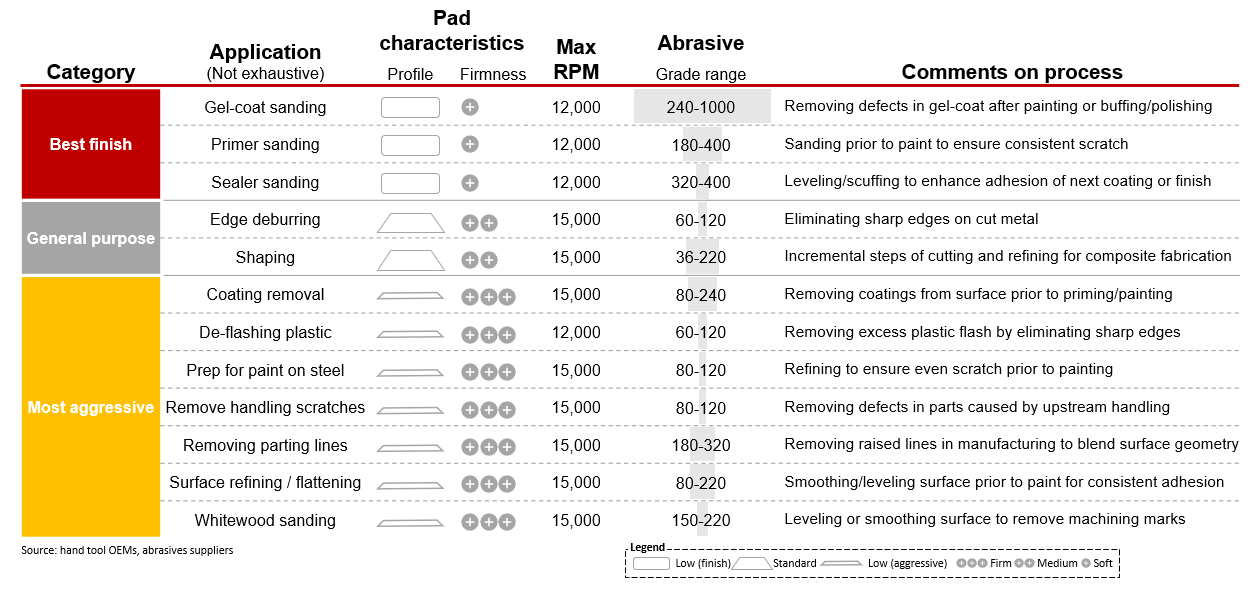

The various shapes are related to the flexibility needed. As the tool runs across edges and surfaces, different pad firmness levels will react differently. See the below chart for more details.

The various shapes are related to the flexibility needed. As the tool runs across edges and surfaces, different pad firmness levels will react differently. See the below chart for more details.

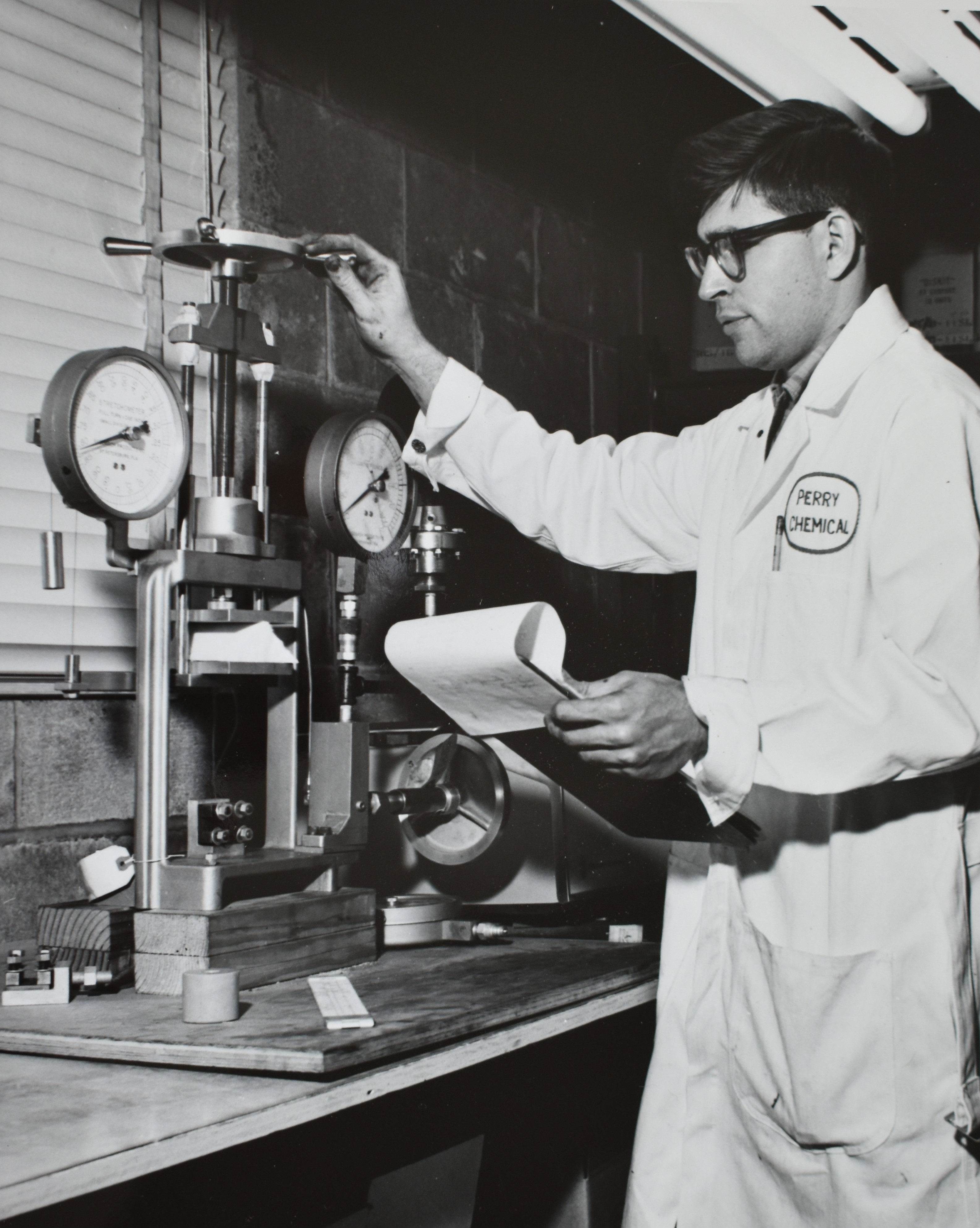

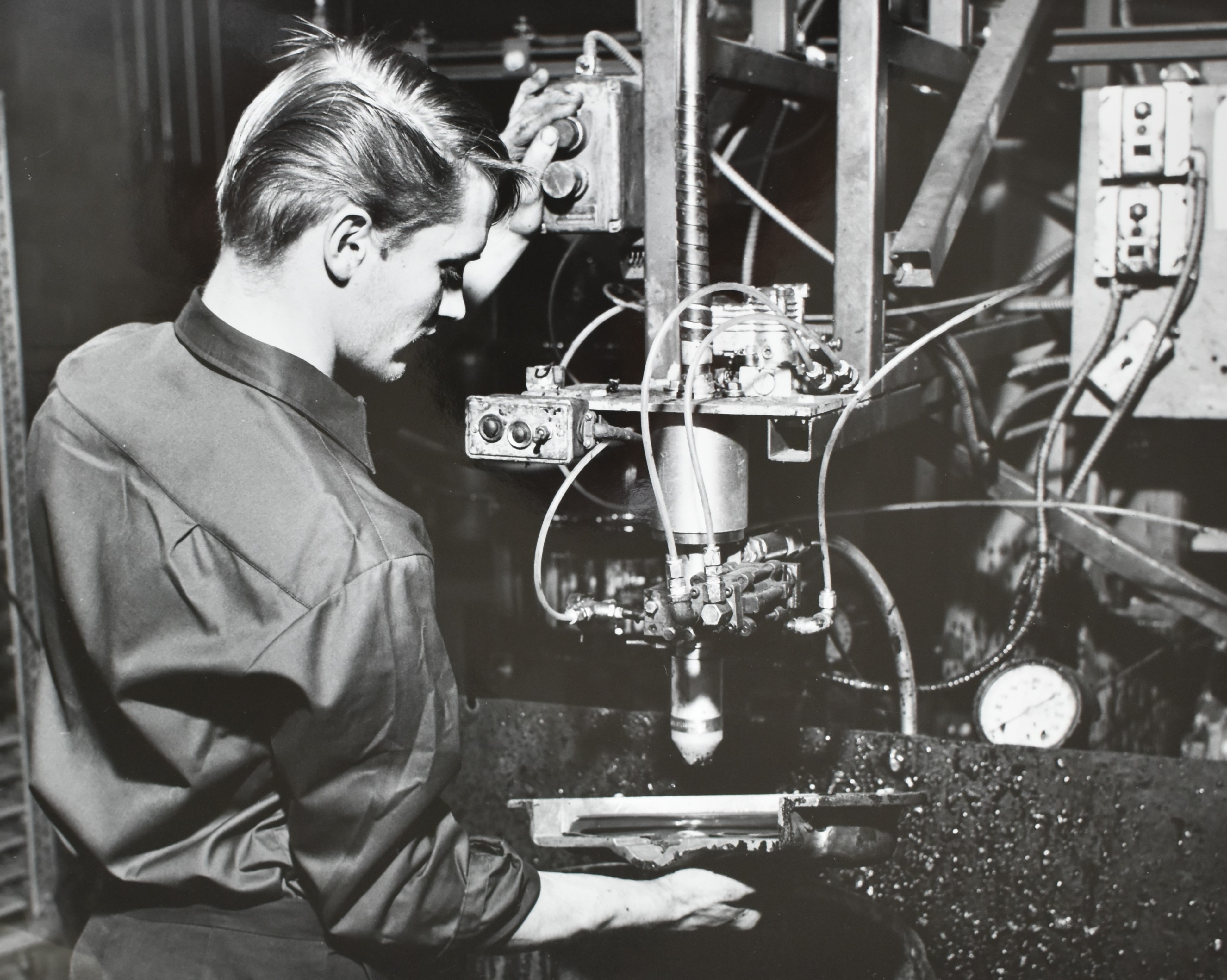

Molded pads are manufactured by pouring liquid foam into molds, bonding the plate, face material, and foam directly together. These chemical and mechanical bonds are extremely strong.

Conversely, fabricated pads are manufactured by gluing premade foam to the face material and plate. In this approach, the total pad strength is only as strong as the adhesive used, leading to higher risks of pad failure in use. This decreases operator safety and increases OEM liability.

At Perry Foam Products, safety and quality are our main focus. To this end, we do NOT manufacture fabricated pads. All of our pads are molded, a sample of which go through rigorous quality testing.

Conversely, fabricated pads are manufactured by gluing premade foam to the face material and plate. In this approach, the total pad strength is only as strong as the adhesive used, leading to higher risks of pad failure in use. This decreases operator safety and increases OEM liability.

At Perry Foam Products, safety and quality are our main focus. To this end, we do NOT manufacture fabricated pads. All of our pads are molded, a sample of which go through rigorous quality testing.

Contact Us

_____________________________

Perry Foam Products, Inc.

2335 South 30th Street

Lafayette, Indiana 47909

_____________________

1-765-474-3404

1-800-592-6614

orders@perryfoam.com

Capabilities

Perry Foam Products offers collaboration and customization on all design specifications, including adjusting our proprietary foam formulations to meet your desired firmness and performance. Our proprietary foam systems enable us to manufacture pads that vary in firmness but maintain structural integrity. We are the leading manufacturer of soft, durable foam.

We also have extensive experience with multi-hole, studded, and random orbital pads across all firmness levels.

Perry Foam Products even developed our own line of one-piece stud washers to increase durability and strength of our pads. Read more of the benefits here.

Custom Features

Firmness

Color

Face Material

Backer Material

Size

Shape/Profile

Special Features

Performance Specs

Packaging